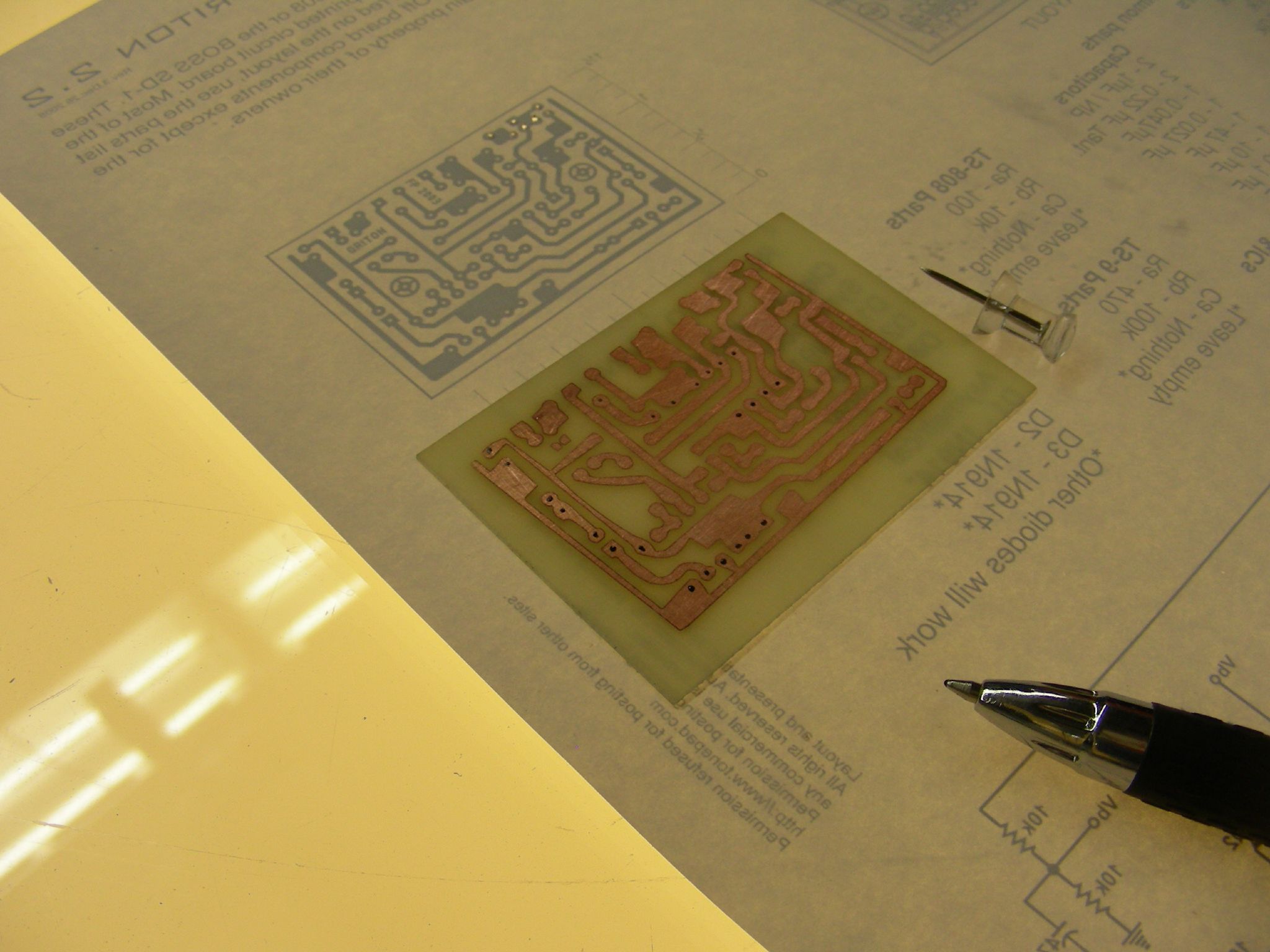

Here’s an easy technique to create a decent quality circuit board. You can design your own circuit traces, or you can find existing artwork of proven designs.

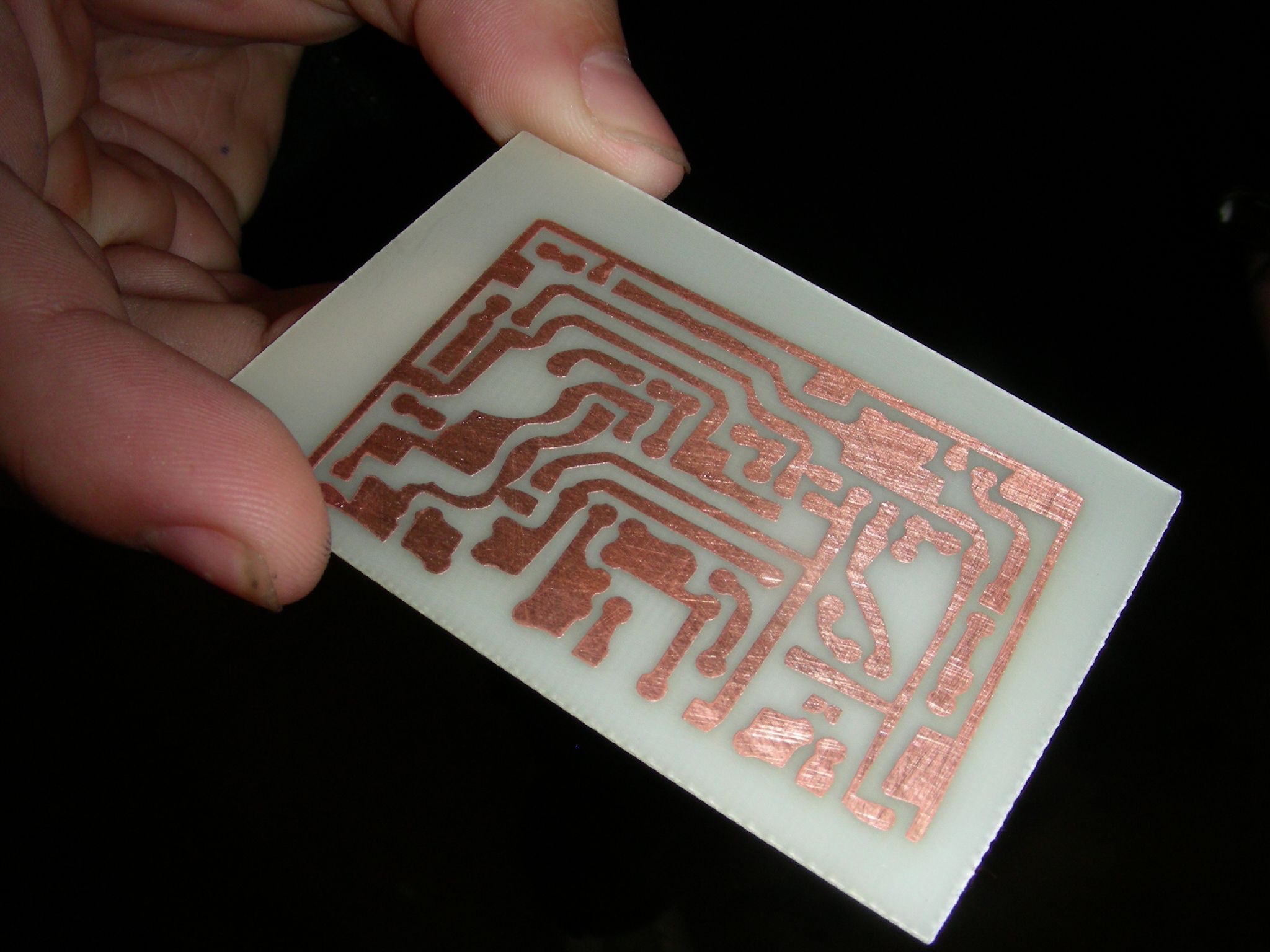

There lots of ways to etch a circuit board, but all of them create a path for the electricity by preserving and removing portions of the copper coating on the board. You might have tried drawing your circuit design on the copper with a pen or grease pencil, or silkscreen-printing it, or transferring toner from a laser printer — and then chemically etching the board. A substance used in this way is called a “resist” because it resists the etchant and protects the copper.

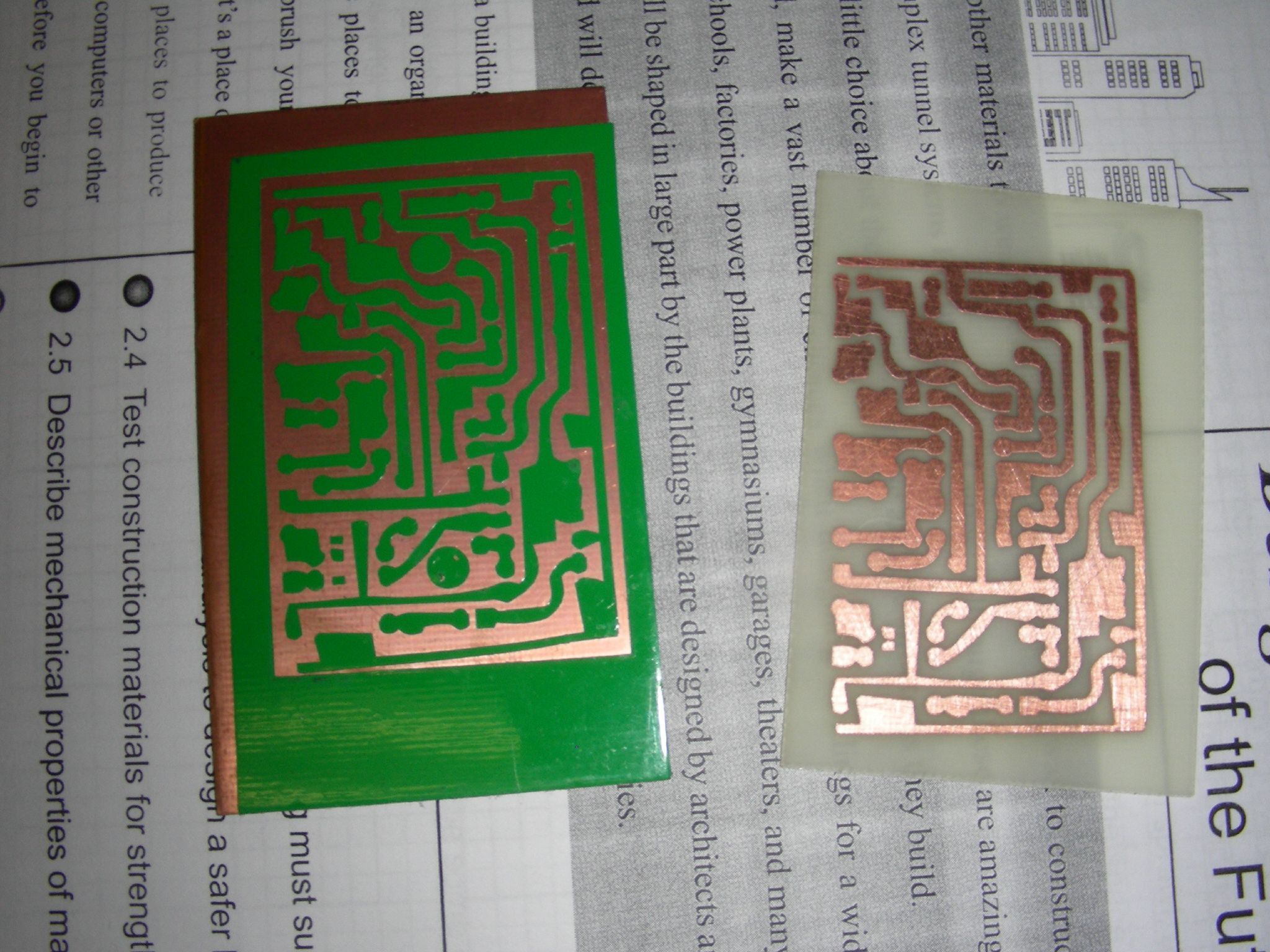

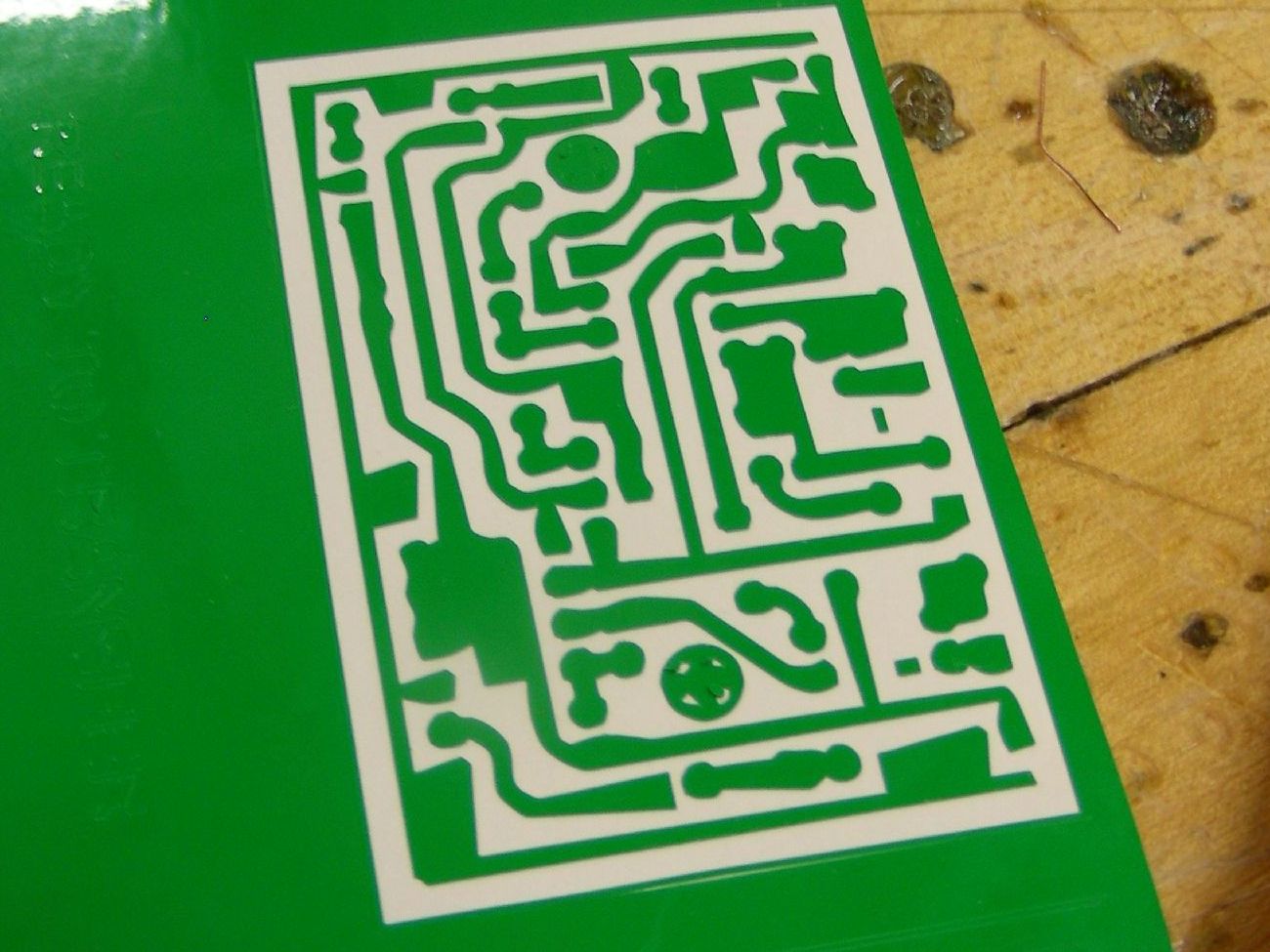

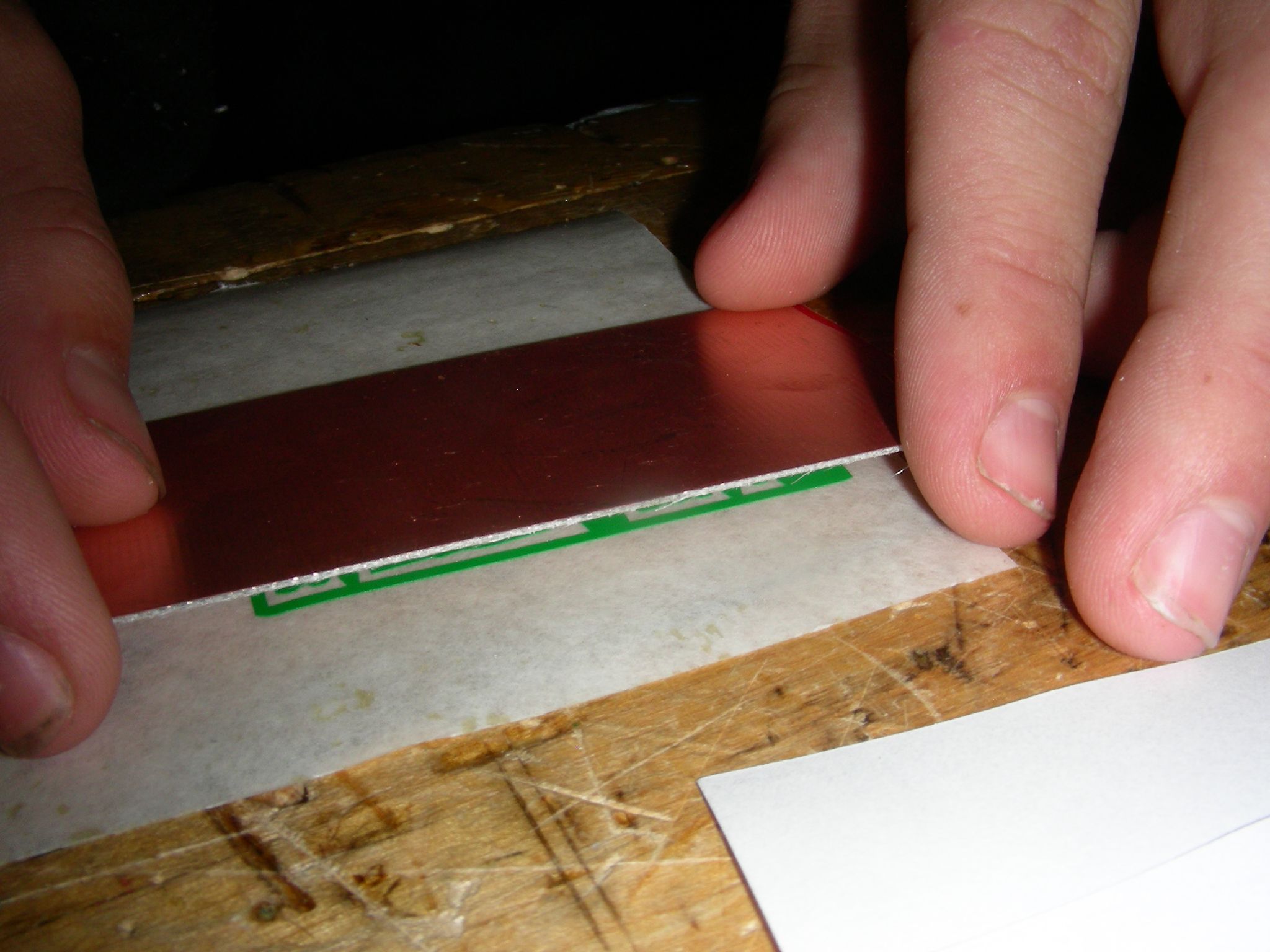

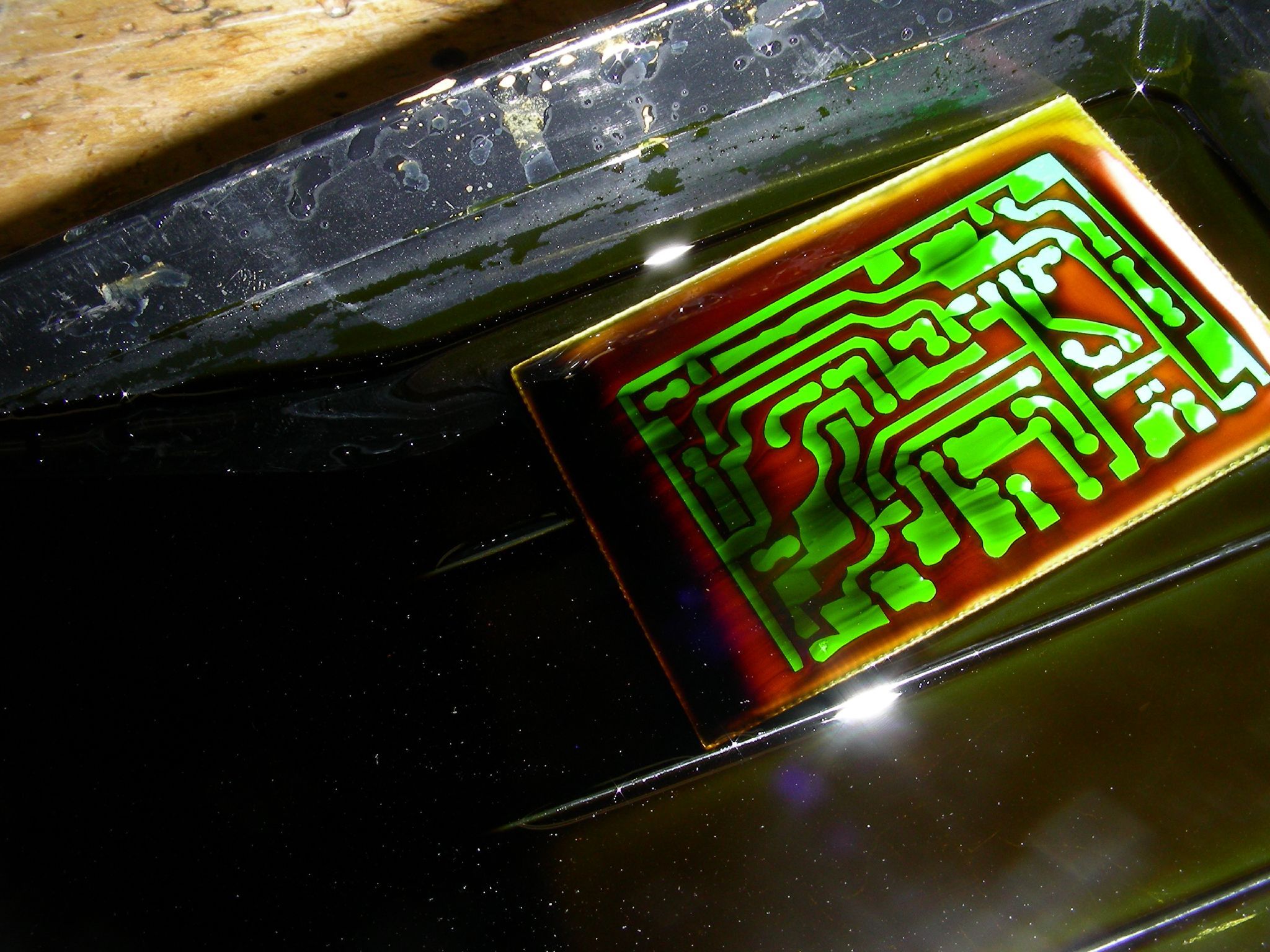

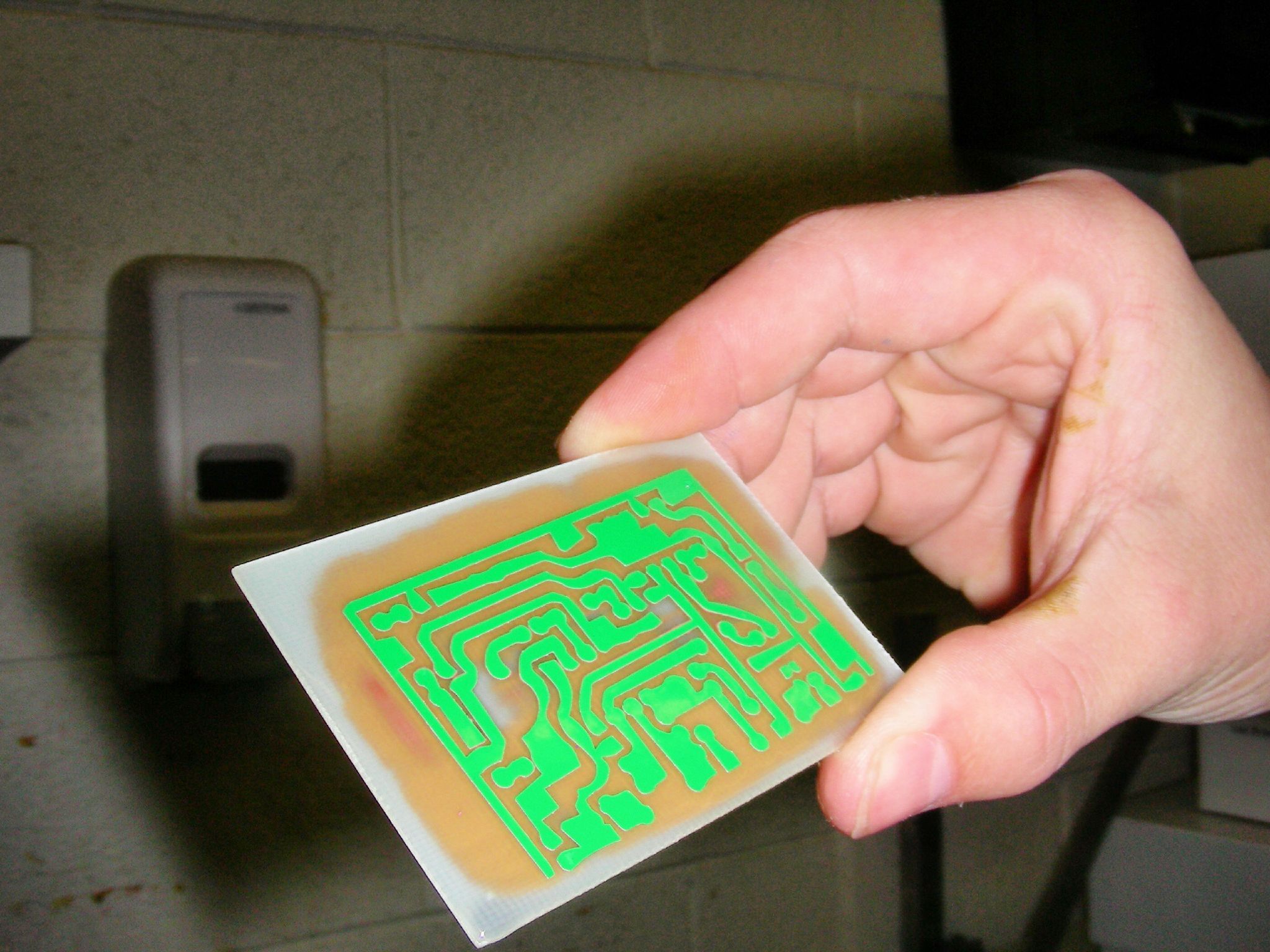

One of the easiest and most consistent methods I’ve found is to use adhesive-backed vinyl from a sign cutter to create the resist. You adhere your circuit trace image directly onto the board, and then immerse the board in a chemical bath. The exposed copper is removed, leaving just the copper traces you want for your circuit.

MAKE Volume 33 features our special Software for Makers section covering apps for circuit board design, 3D design and printing, microcontrollers, and programming for kids. Also, meet our new Arduino-powered Rovera robot and get started with Raspberry Pi. As usual, you’ll also find fascinating makers inside, like the maniacs on our cover, the hackers behind the popular Power Racing Series events at Maker Faire.

Try your hand at 22 great DIY projects, like the Optical Tremolo guitar effects box, "Panjolele" cake-pan ukelele, Wii Nunchuk Mouse, CNC joinery tricks, treat-dispensing cat scratching post, laser-cut flexing wooden books, sake brewing, growing incredibly hot “ghost chili” peppers, and much more.

On newsstands now, by subscription, or available in the Maker Shed